Sereng Engineering

Technology LS3D - BIM Platform

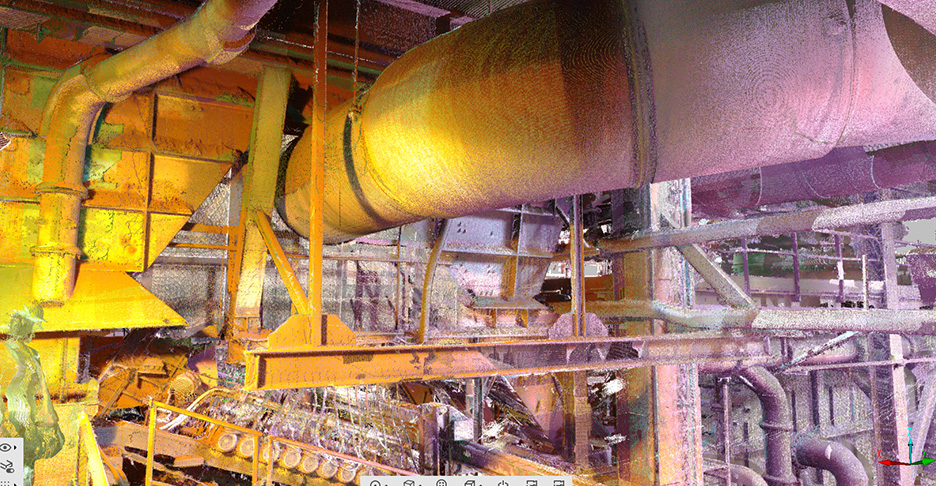

Digital Laser Scanning (LS3D):

- Point cloud

- 3D mockup (scale-model)

Digital laser scanning:

- Project database

- Integrated engineering software

The LS3D technology offers benefits such as agility, and high quality in detail of the elements collected in the field and storage of these in point clouds. This technology gives us excellent precision in the execution of as- built and in the development of further engineering processes.

This technology works in 04 steps, being:

- Scanning - Brownfield Data Capture

- Registration - Scene alignment

- As-built modeling

- 3D Engineering - Removal of Existing Structures / Virtual Assembly

Use of 3D technology in engineering development - BIM Platform

Sereng, aiming to add value to the products offered to its clients, combines its vast experience in the execution of multidisciplinary projects, using state-of-the-art technology in the development of its engineering services, in order to offer quality solutions that fully meet the needs of each project.

The technology currently used by Sereng is based on the use of hardware and software tools that use processes and concepts from the Building Information Modeling (BIM) platform.

The benefits can be achieved in all the dimensions of this cycle, emphasizing:

The technology currently used by Sereng is based on the use of hardware and software tools that use processes and concepts from the Building Information Modeling (BIM) platform.

The benefits can be achieved in all the dimensions of this cycle, emphasizing:

- Engineering: Increasing quality, improving efficiency and eliminating interference to reduce rework in the deployment phase;

- Material management: Minimize inventory, eliminate waste and surplus, maximizing cost efficiency;

- Deployment Management: Efficiency in assembly, predictability and visibility. Access to reliable information. Possibility to simulate virtually the movement of equipment and loads;

- Information and Asset Management: Support in the elimination, minimization or mitigation of operational risks, and to guarantee the reliability and efficiency of production. Securely and reliably support, providing Operation and Maintenance teams with quick, easy and intuitive access to asset information;

- Brownfield Data Capture: Rapid, reliable and accurate capture of the physical "as-is" environment to provide engineering-oriented data for major redesign, efficiency improvement planning, and operational compliance;

- Asset Modifications: Ensure that asset modifications can be planned and implemented quickly, efficiently and with minimal downtime;

- Security: A clear advantage of the security aspect comes from the fact that with the 3D model the maintenance team can remotely simulate the most varied operations without exposing the team to the inherent risks of an area in operation;

- Health: Since all the preparation is done in a controlled environment, without the people involved having to be exposed to the environment of an area of operation. This itself already guarantees a lower rate of exposure to an uncontrolled environment, even if it is an area without health risks, at least there is a reduction of stress;

- Costs: All preparation can be done with a shorter number of hours, without having to take the teams to the field. This contributes significantly to the reduction of mobilization time and greatly facilitates the coordination of these operations;

- Environment: It can be said that a lower generation of noise, vibration, and disposal, among many others, shall reduce the impact on the environment.